Cyclone XL

Cyclone XL

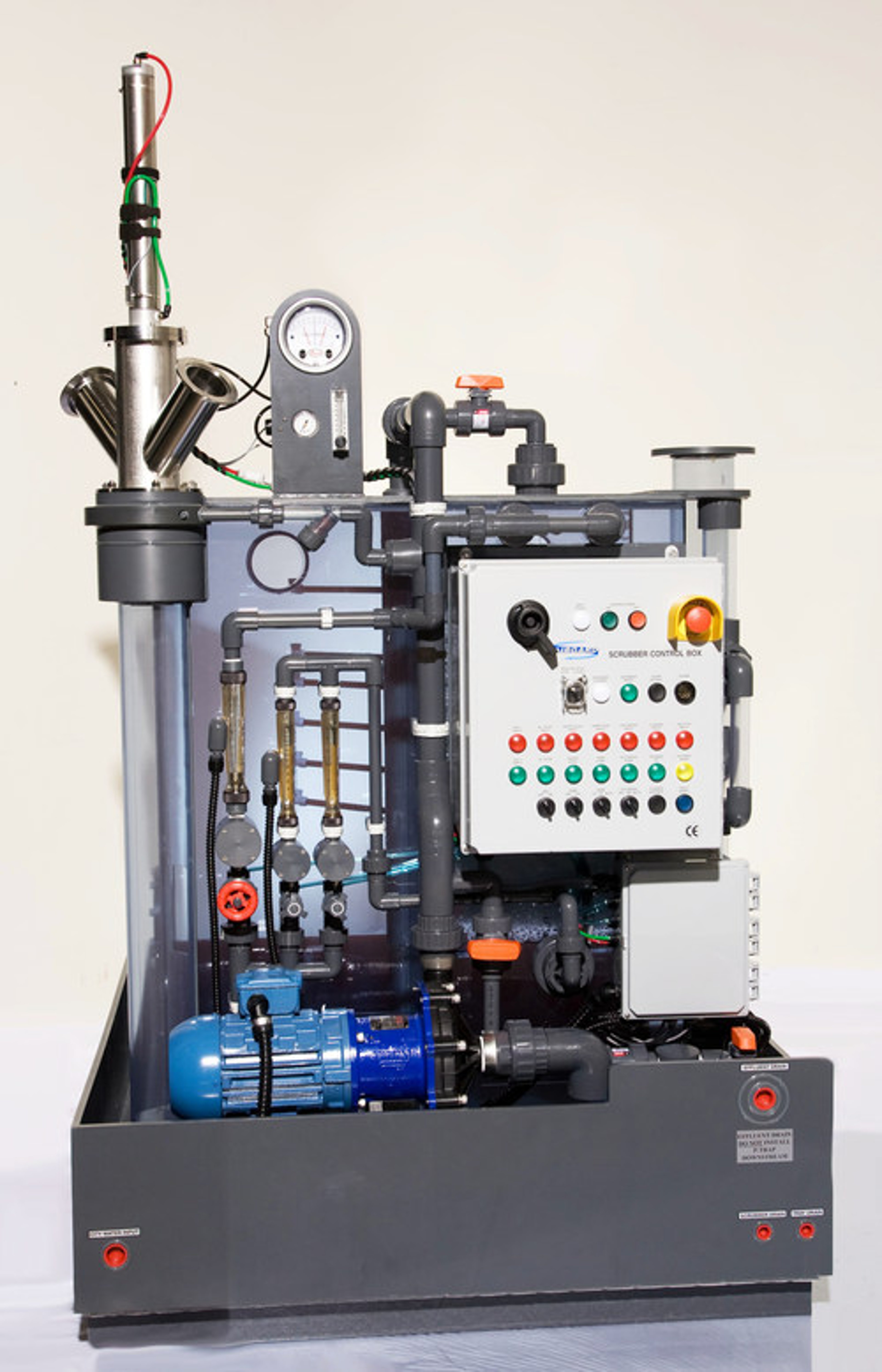

The Cyclone XL features a coarse-spray, high-flow nozzle that coats the first scrubbing chamber and removes bulk impurities. Strategic position increases efficiency, minimizes water use and eliminates foam.

- High Flow Capacity: Up to 5000slm flow capacity without loss of efficiency. More than 5 times most POU systems.

- Gas Inlet Devices: Ambient or high temperature gas inlet devices minimize rate of restriction and automatic gas inlet plunger removes restrictions without process interruptions.

- Packed Column: The final polish. Packing requires no maintenance or replacement.

- Second and Third Scrubbing Chambers: Eleven fine spray, high velocity nozzles ensure effective removal of impurities.

- First Scrubbing Chamber: Coarse spray, high-flow nozzle coats chamber and removes bulk impurities.

- Fresh Water Input: Strategic position increases efficiency, minimizes water use and eliminates foam. Three flow stages to match process parameters.

- Pump: Corrosion resistant, high-output and long life. Recirculates 25GPM.

- Sump Geometry: Unique pump input, drain, and fresh water input locations prevent foaming, sediment, and minimize water use.

- Small Footprint: 47.2” x 53.35”

Encompass

Leveraging our unique value proposition in wet scrubbing, Exentec has introduced Encompass, our first thermal product line

Cyclone XL

The Cyclone XL features a coarse-spray, high-flow nozzle that coats the first scrubbing chamber and removes bulk impurities.

Vortex

The Vortex is Exentec's original scrubber model and includes our specialized gas entry device

Gas Inlet Configurations

Exentec provides heated, poly etch CVD, high temperature and epitaxial inlets